From the start of a project, we deploy all in-house knowledge from concept and system design, parts manufacturing and assembly & test in dedicated teams.

We start from a solid system architecture and design and verify and validate every step along the way, including complex physics modelling, prototyping and proof of concept demonstration.

This has allowed us to build a track record of executing complex and challenging innovation projects in a predictable way.

Our expertise

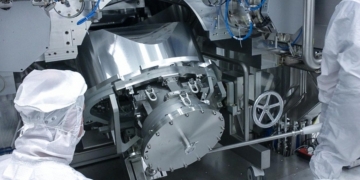

- Integration in the domain of nanometer-precision mechanics, optics and mechatronics systems.

- Expertise in extreme environments, including rapid temperature changes, gas and heat flows, and ultra-clean or ultra-high vacuum conditions.

Our services

- Feasibility and concept development

- Module and system design (incl. software)

- Testing and validation

- Product lifecycle support

- Customer IP development

Our competences

- Precision mechanics & mechatronics

- Software, control & electronics

- Optics & opto-mechatronics

- Physics (vacuum, heat, pressure, radiation) & ultra-clean system design

- Cleanliness-focused design (particles, chemicals) & DfX (assembly, manufacturing, cost).

IT STARTS WITH PHYSICS​

Understanding the true nature of the process, the physics involved, and the interaction between process and machine.​

- Physics Modeling: Modeling product-physics interactions to derive fundamental system and process specifications. Experimental verification, using proof-of-concept experiments.​

- Cleanliness: Keeping particle and molecular contamination under control requires an integrated approach that starts with the concept, through design and manufacturing execution.

- Design: System engineering approach facilitates ‘concurrent engineering’ ensuring risk management and fast execution. Experience and a balanced supply chain enables lab-to-fab.​

38 years of experiece in research, development and engineering

50% of our staff is dedicated to R&D

2300M2 of offices and labs in our TAQ building

we motivate our teams to act as as the extended R&D department of our customers

We challenge our clients R&D questions and develop tools and systems that fullfill true needs

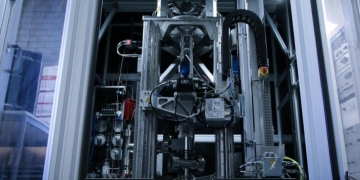

project examples

feasibility study

- In a multi-year research program we supported R&D of our customer.

- Our team of 6 FTE on average was involved in thermal modelling, gas flow analysis, concept design of printheads and stages in an ultra clean vacuum environment.

- Proof of concept was verified and a new generation of research equipment was designed, built and integrated in the research laboratory of our customer, which was key for the market introduction of a new generation of products.

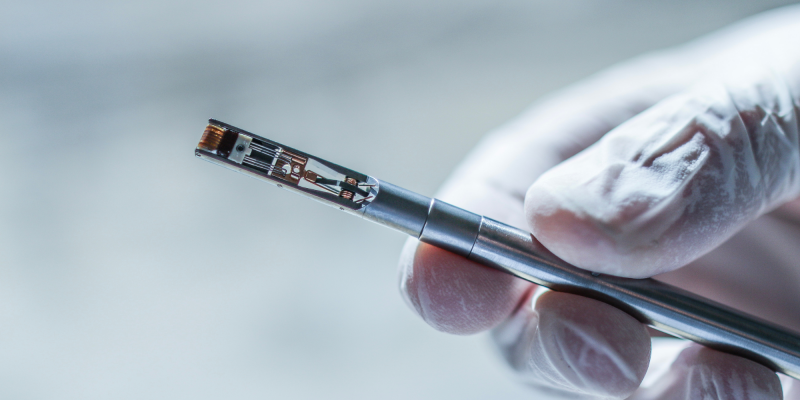

IP creation

- The combination of hologram technology in an opto mechatronics module lead to a world wide approved patent of a high resolution measuring device.

- Our team foscused on concept development, patent study, patent application, the industrialisation of the sensor and developing an assembly line for pilot production.

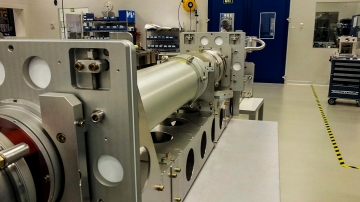

ultra-stable measurement

- For verifying sensor-concept-accuracy our team developed a concept to reach extreme stability in measurement environment, enabling stability down to picometer levels over long periods of time (10^-12 sensitivity).

- Handling large masses, vacuum cleanliness, isolating and damping of vibrations, predictable material and thermal (creep) behavior were all taken into account.

positioning components

- In semicon production equipment, specific elements are getting larger.

- Positioning elements with accuracy and stability becomes more important.

- Our team developes concepts for stable positioning and minimal deformation, operating in an ultra-clean vacuum environment.

- We develop, build and install holders including related tooling and automation equipment.