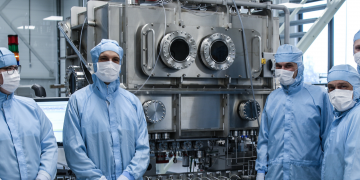

We specialize in series production, high mix - low volume, functional models, and prototype machines, all while meeting various cleanliness requirements. Our success is driven by early involvement in supply chain management and manufacturing engineering. From the start, we assemble balanced project teams with experts from R&D, Advanced Systems, and Precision Parts, ensuring seamless project execution. Key suppliers are engaged early, fostering transparent partnerships built on quality, precision, and on-time delivery. Our assembly teams excel in ultra-clean, high-precision assembly, working closely with R&D for full integration. We also offer in-house RGA facilities for certified analysis and cleaning, accommodating both small and XXL dimensions.

our expertise

- We combine concept development, engineering, TPD, manufacturing, and assembly.

- We link to in-house manufacturing and trusted external suppliers.

- We design supply chains and validate partners and deliveries on QLTC.

Our services

- Assemble, test, qualify, and validate complex high-tech systems, modules, and (sub)assemblies

- Deliver build-to-print and build-to-order solutions, ranging from high-mix, low-volume to series production

- Provide comprehensive service and maintenance for all delivered system.

our competences

- Manufacturing Engineering

- Supply Chain Engineering

- Production Engineering

- Integration & Validation

- Service & Sustaining

Founded in 2016

100+ manyears before TPD release dedicated in the biggest program so far

members of staff in our Advanced Systems teams

1.000M2 cleanroom space + 2.500 M2 clean assembly space

200+ external suppliers in our supply chain network worldwide

Quality always first

- We focus on reliable predictable manufacturing processes.

- Measurable quality t.i. validation before delivery, according to customer specs Varying from standard 3D measuring up to full RGA and dynamics analysis

assembly facilities

- ISO 5/6 surface 600m2

- ISO 7 surface 200m2

- ISO 8 surface 4x50m2

- Laser safety environment

- Assembly hall footprint of 2500 M2

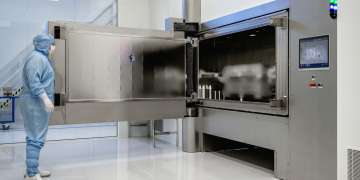

RGA as a Service

- RGA S & XXL

- Parts up to 2000 x 2000 x 1000 mm and 1250 kg.

- Bake-out temperature: 200 ºC

- Approved GSA cleanliness grade 1+2

- Fast lead time: typically two weeks for Grade 2 Cleaning + RGA measurement.